Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

Patent of Invention

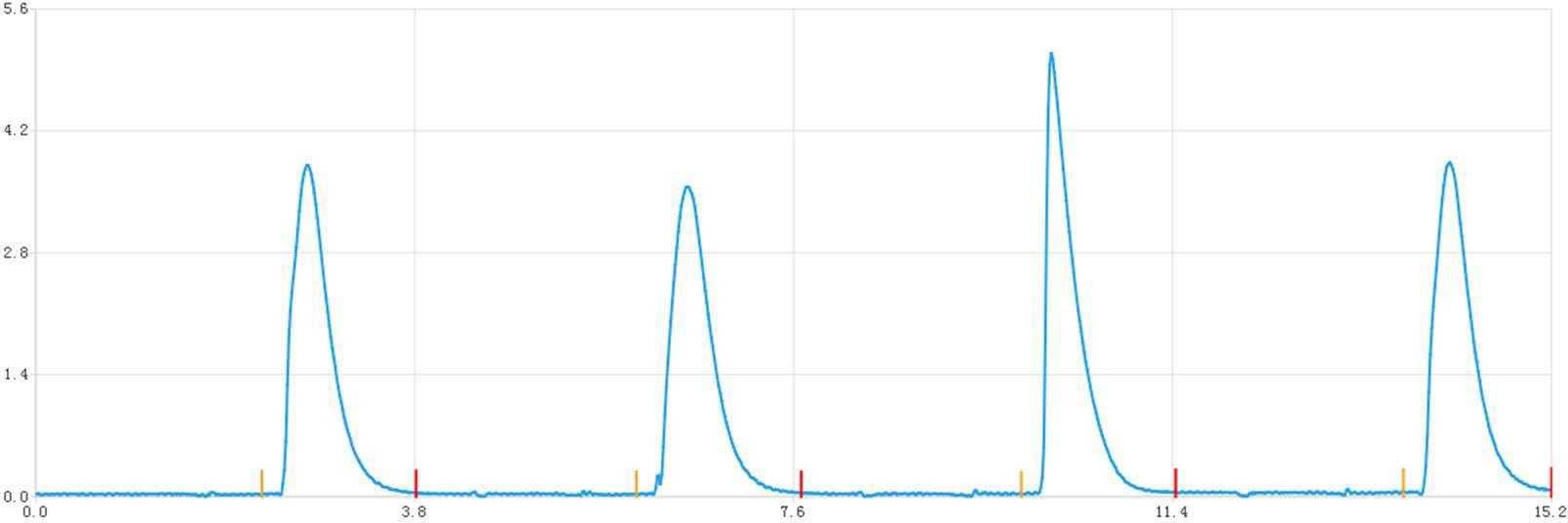

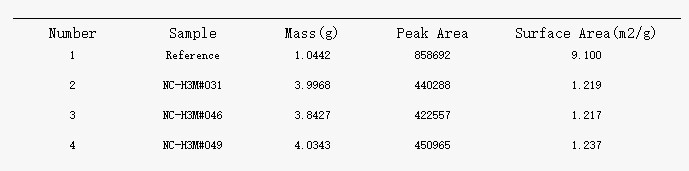

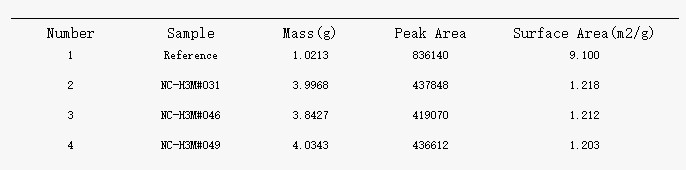

Accurate adsorption measurements based on sharp peak detection eliminate errors caused by incomplete desorption. Ideal for low surface area samples such as ternary materials and battery electrode materials. (Patent No. 20140320453.2)

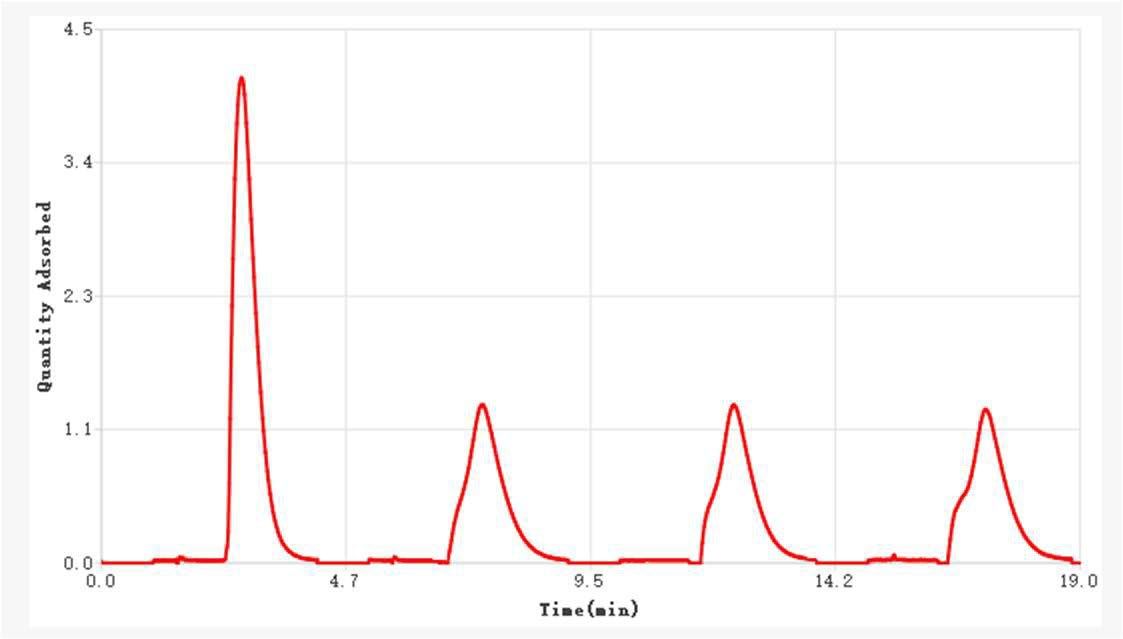

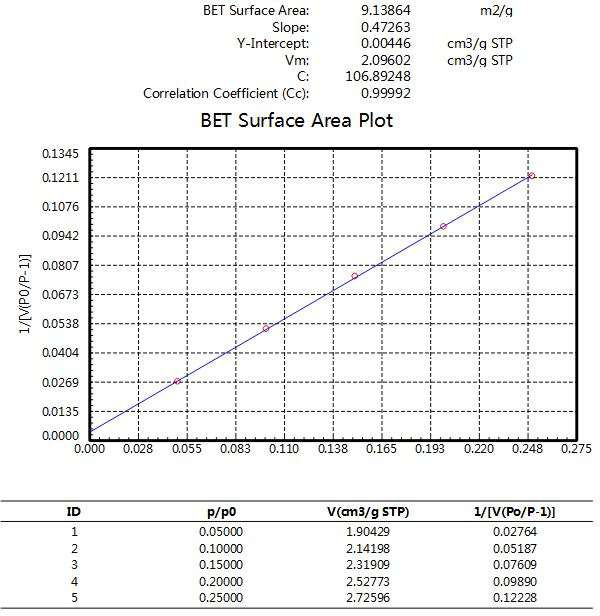

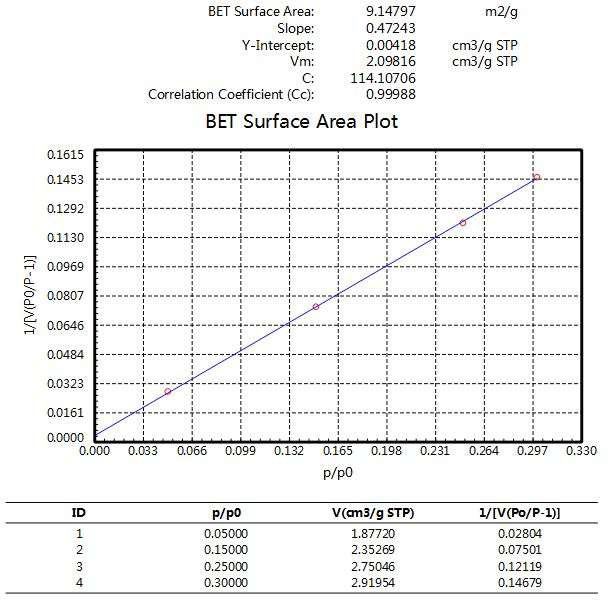

Automatic Nitrogen Partial Pressure Control

Surface DX 400 is equipped with high-precision mass flow controllers to automatically regulate nitrogen partial pressure during BET surface area measurements. This ensures stable and accurate gas flow across the sample surface, delivering consistent and reliable adsorption results with minimal manual intervention.

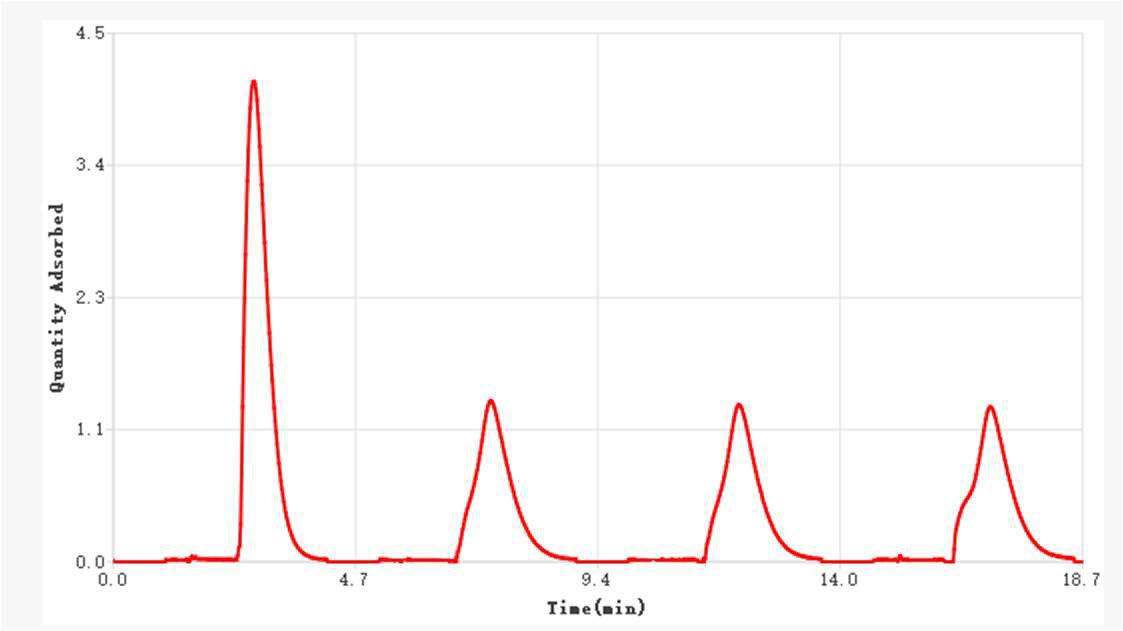

Four Parallel Operating Analysis Stations

Run up to four samples at once with independently controlled stations. Achieve unmatched throughput with consistent test conditions and result repeatability better than ±1.0%.

Anti-Elutriation Technology

A built-in anti-contamination unit prevents sample particles from entering the instrument’s internal gas line, ensuring operational reliability and long-term cleanliness.

Optional Sample Preparation Unit

External sample preparation device with four-degas stations can remove adsorbed contaminants from surface and pores of samples with heating in flowing gas/vacuum. Temperature can be set and controlled from ambient to 400 ºC.